Technology

Core Technical Capabilities

Epoch centers on backlight product development, supported by strong technological research. From optical design and processing to automated cross-domain integration, the company advances innovation through a comprehensive R&D environment and advanced equipment.

Building a Smart Factory Where People and Machines Collaborate

Backlight production is inherently labor-intensive, yet EPOCH excels in both manufacturing technology and

production management. We continuously stay attuned to new technologies and emerging applications. Through our

integration-driven talent, we actively apply new tools and information—creating greater value for customers

externally and enhancing efficiency and job fulfillment internally through human-machine collaboration.

We encourage our team to think creatively and experiment boldly, developing into irreplaceable integrative

talents. “Growing through setbacks and learning through failures” is part of our DNA.

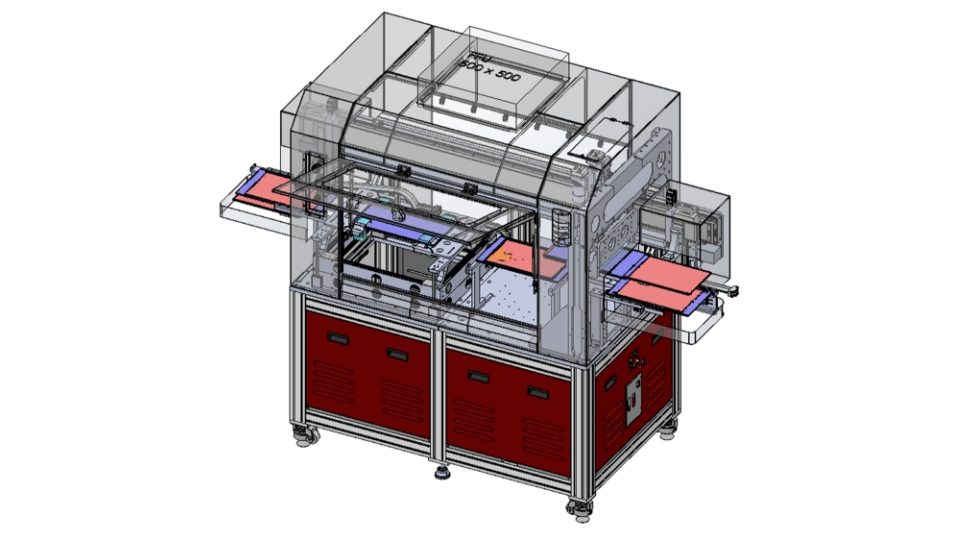

3D Mechanical Design and Control Integration Technology

Built upon more than 20 years of backlight manufacturing expertise, we design mechanical systems optimized for factory production. By integrating PLC , we develop semi-automatic and fully automated jigs and equipment tailored specifically for backlight manufacturing.

Robotic Arm Control and Integration Technology

By designing custom jigs and integrating them with various robotic arms, we reduce labor requirements and eliminate repetitive tasks. The system can also respond to production needs in real time, enabling fast, autonomous adjustments and changeovers.

Click the video link in the image to learn more >>

Production Data Visualization Technology

With the rise of Industry 4.0, real-time monitoring and management of massive production data has become essential. We proactively develop related technologies and adopt various visualization tools, integrating data collection into our automated equipment systems. Through centralized or edge-based database management and in-house application development, we achieve fully visualized and actionable production data management.

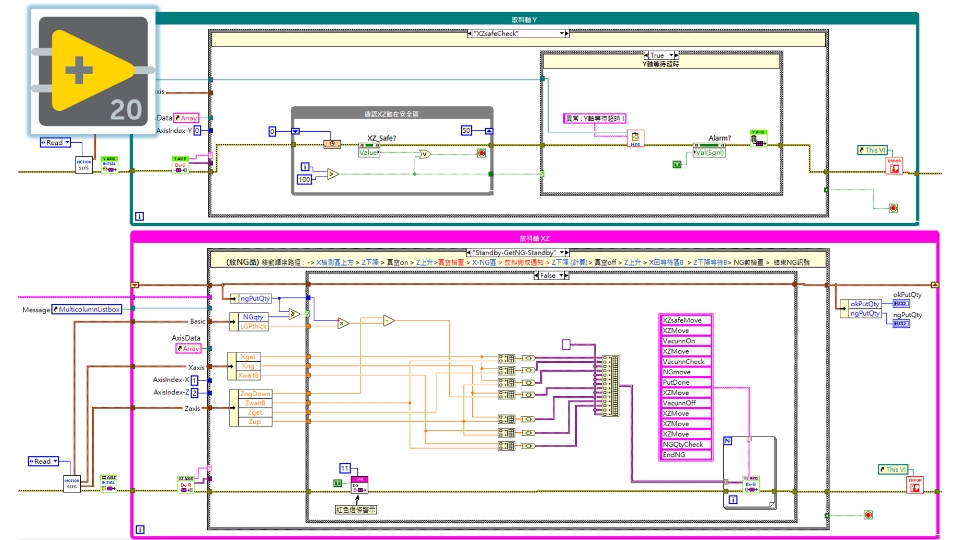

Software Development and Application Technology

Beyond hardware foundations, automation relies heavily on software integration — including database management, data analysis, robotic vision positioning, and image-based product inspection algorithms. Using LabVIEW (developed by National Instruments) as our core development platform and integrating additional programming languages such as C++, Java, and Python, we deliver comprehensive solutions that seamlessly combine software and hardware.